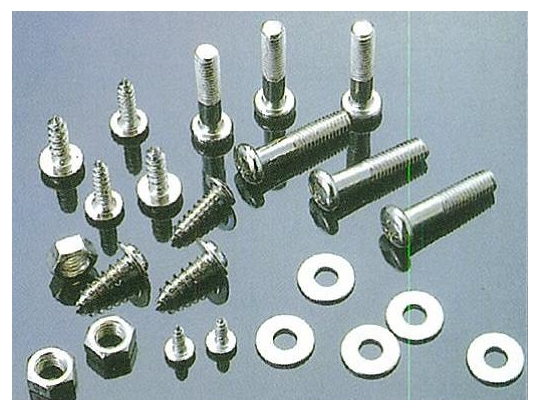

Cold heading wire is mainly used for various kinds of fasteners and pins for construction & automotive use as well as precision disc use. It has excellent corrosion resistance and mechanical properties depending on the grades. In order to obtain good-shaped upsetting and threading it is very essential to select the most suitable grades with highest quality.

If required by customers, we can coat the wire with a special thin film which provides excellent lubrication for cold heading and also provides excellent lubrication for cold heading and also provides threadability including forward & backward browing, longer tool life with less clogging and easier cleaning.

Characteristics

High formability

Low working stress

Excellent surface quality

Most proper hardenability and low tool wearing

Chemical Composition (%) C Si Mn P S Ni Cr ≦0.08 ≦1.00 ≦2.00 ≦0.045 ≦0.03 8.00-10.50 18.0-20.0